Nanobubbles and crystal growth monitored in graphene pockets

July 24, 2017 - Ulm University physicists and biologists enhance the understanding of dynamics and internal conditions of liquids encapsulated between two graphene sheets. By filming the "graphene liquid cells" [1,2] at atomic resolution in HR-TEM at lower acceleration voltages of 80 kV, they were able to identify constituents of the fluid and thus study the interior pressure and temperature conditions.

A team of scientists lead by SALVE microscopy center’s director Prof. Ute Kaiser reported a detailed study of crystal formation and dynamics in graphene liquid cells – a system that facilitates the study of growth and transformations of materials in three dimensions. [3,4]

“Graphene liquid cells are a sample carrier that allows us to easily and freely observe dynamics and structural reshaping of nanocrystals,” said Kaiser, a professor of materials science and expert in the field of investigation of sensitive matter with electron microscopy. “We’re interested in not just observing materials in a particular state, but also their formation and phase transitions.”

As one of the first applications graphene liquid cells were used for imaging the growth, coalescence and structural transformation of a Pt nanocrystal in high-resolution TEM (HRTEM). [3,4] Important results were shortly afterwards the confirmation of the Lifshitz-Slyozov-Wagner mechanism for these nanoparticles. [5] and the first real-time monitoring of the conversion of CuSo4 into CuO and Ca(OH)4 into CaO at the atomic level [2], and initial results regarding the dynamics of nanobubbles trapped in the graphene pockets and the gas transport between them. [6] The pressure in the nanobubbles was estimated to be between 140 and 400 MPa, depending on the size. But the fundamental understanding of the dynamics, the exact pressure conditions, the heat transport and the interaction with the electron beam is still lacking today.

Kaiser says the new study now helps researchers understand the properties inside the new reaction vessels, which will also lead to better understand and investigate the behavior of matter very close to surfaces, which can also be found in nature. The pockets make it possible to study matter under extreme pressure and constant supply of various substances from the solution using modern transmission electron microscopes [7,8]. As the material graphene, which is used for encapsulation of the liquid [5,6], is no longer stable at accelerating voltages above 80 kV in the TEM [9], the use of low-voltage aberration-corrected TEM is essential. Within the liquid cells, radiation damage is considerably reduced. It is possible to study materials that would be destroyed when freestanding in the TEM after a short time, such as molecules [9]. Previous experiments with the inclusion of 2D materials between 2 graphene layers have shown to reduce radiation damage by up to 3 orders of magnitude for 2D MoS2 [10,11 and this news article].

"Graphene liquid cells represent the latest thinking in sample preparation for electron microscopy," says Kaiser. "This method and its capabilities will serve a diverse community of researchers from physics and chemistry to biology."

Identification of the nanocrystals

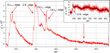

Figure 2 shows an AC-HRTEM image sequence of a growing crystal from the aqueous solution (single-distilled water) taken at 80 kV. To chemically identify the crystals, electron energy loss spectroscopy (EELS) experiments were performed. Calcium (Ca), sulfur (S), carbon (C) and oxygen (O) were found (Figure 3). The characteristic signal at 165 eV indicates S, the signals at 346 and 350 eV detect Ca, the peak at ~ 284 eV corresponds to the C signal due to graphene encapsulation of the solution, and the O signal is at 532 eV. In addition, no further signals from other elements were detected.

Considering all known Ca, S and O compounds, the EELS data in combination with the images shown in Figure 2a-c can only be explained by an orthorhombic anhydrite crystal in the [100] projection. Furthermore, the HRTEM image agrees with the [100] diffraction pattern of CaSO4 (Figure 4). For the simulation, a crystal thickness of three unit cells (2.1 nm) was assumed. The so-called AII phase in Fig. 4a is consistent with the experimental AC phase in the HRTEM image in Fig. 4 (b) and in the diffraction pattern (FFT) Fig. 4 (c) within the specified confidence interval of the measurement.

Crystal formation of CaSO4 @ liquid

In the study, Kaiser's team was dealing with the investigation of the dynamic processes. As the imaging is done in a liquid, material is constantly changing from the crystalline to the dissolved state. Due to the interaction with the electron beam, bubbles of liquid also move within the graphene pockets. In the pictures Fig. 2 (a) - (c) a growth rate of about 0.7 nm2/s was measured. The growth rate increases in the pictures (e) - (h) to ~ 1.05 nm2/s. Looking at the two CaSO4 crystals in Figure 2, one finds that they are initially inclined to each other and thus prevent each other from growing until the thicker area (higher contrast) transforms the thinner part. After reshaping, an alignment (Figure 2d) disappears, possibly due to the system's tendency to reduce its surface energy. Thereafter, the growth rate increases by a factor of ~ 1.5. These processes are consistent with the Ostwald ripening process and the Lifshitz-Slyozov-Wagner theory, which predicts the reduction of energy at the boundary [6].

An interesting observation was that the enclosed solution remains liquid despite the surrounding high vacuum with a pressure of only 10-5 Pa. This is surprising since at room temperature water is in the liquid state in the pressure range from kPa to MPa. [12] It can be concluded that a graphene liquid cell must be considered as a closed system that generates its own internal pressure due to the van der Waals interaction between the two graphene layers.

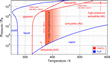

Since the material was identified as CaSO4, one could use the complex phase diagram of this material for the estimation of temperature and pressure(Figure 5). Accordingly, several phases are possible for the crystal, such as hydrous gypsum (CaSO4 • 2H2O), hemihydrate (CaSO4 • 0.5H2O), or the anhydrite phase (CaSO4). [13,14] Anhydrides exist in different phases, including the AIII phase (γ-CaSO4) with hexagonal structure, the orthorhombic AII phase, and the monoclinic, high-pressure AI phase. [13,14] Figure 5 shows the pT phase diagrams for water and CaSO4, which reflects the classical crystallization conditions, whereby these must not necessarily be valid on the nanoscale. The required temperatures and pressures for the transition between the different phases are, for example, at 42-60 ° C and 105 Pa from gypsum to γ-CaSO4 and the triple point at 235 MPa and 80 ° C, where 3 phases should be present simultaneously. Based on the phase diagrams, one would have to conclude that the pressure and temperature in the graphene liquid cell is in the range from ~ 100 kPa to ~ 230 MPa and 100-150 ° C, respectively.

The value of ~ 230 MPa agrees very well with literature values for the pressure in graphene liquids. [1,6] From previous studies, the scientists from Ulm already knew that the van der Waals pressure can be estimated as PvdW ≈ EAE / d [15], where the adhesion energy, EAE, of a monolayer of graphene is about 45 meV / Å2 [16] and the distance between 2 graphene layers d is approximately ~ 3.4 Å [17]. This results in a value of up to 2 GPa for the pressure between 2 graphene layers. Taking into account a mean distance of 20 Å between the graphene layers through the trapped water, [18] a van der Waals pressure of about 360 MPa results, which is in the same order of magnitude as literature values and the experimental values determined from the phase diagram.

However, the p-t-diagram-based simple estimation does not provide any reliable values for temperature. A temperature of 100-150 ° C for crystallization in a graphene-pocket is unlikely, since direct heating due to the electron beam in very thin materials is low [19] and because graphene has high thermal conductivity, which should effectively dissipate the produced heat [20]. However, by theoretical calculations and experimental data it has already been shown, that the melting temperature of nanoparticles is much lower than that of the macroscopic solid [21,22].

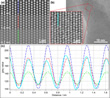

In fact, the dependence of the phase transition temperature on the dimension of the material has already been quantitatively investigated [23,24]. The ratio of surface to volume is decisive here. Especially the thickness D and the 2-dimensional material thickness r determine the transition temperature according to

Tn = T0(1 − 3r/D)

where T0 is the transition temperature of the corresponding macroscale and TN the temperature of the extremely thin ("2D") material. In Fig. 6, Tn is shown as a function of the thickness D of the anhydrite film. The different curves, red and blue, correspond to the values T0 = 150 and 100 ° C, respectively. T0 is in the range of 24-37 ° C at a thickness of 1.4 nm, and in the range of 50-74 for a thickness of 2.1 nm. The estimated temperature reduction for a 2.1 nm thin anhydrite thus agrees with the expected temperatures for the sample in the electron microscope.

From the HRTEM images it is possible to estimate the thickness of the crystals. For this purpose, the scientists performed image simulation for the relevant thicknesses of 1 (0.7 nm), two (1.4 nm) and three unit cells (2.1 nm) (Fig. 7a). The comparison of experiment and simulation showed the best agreement with a thickness of two unit cells (Figure 7c). However, contrast fluctuations between individual atomic series are clearly visible, which is why the scientists assumed a thickness between two and three unit cells. This is in good agreement with their previous studies [21]. Due to the smaller thickness, the encapsulated anhydrite can be considered a quasi-two-dimensional crystal. The determined thickness is also in good agreement with the results of dimensional dependence of the melting temperature.

The team of biologists led by Prof. Kerstin Leopold from the Institute of Analytical and Bioanalytical Chemistry was busy explaining the molecular processes. Other researchers include Tibor Lehnert, Michael K. Kinyanjui, Anita Ladenburger, Dimitri Rommel, Katharina Wörle, and Felix Börrnert.

Researcher Contact: Ute Kaiser, ute.kaiser@uni-ulm.de, +49-731-50-22950

Publication reference: Lehnert, T., Kinyanjui, M. K., Ladenburger, A., Rommel, D., Wörle, K., Boerrnert, F., ... & Kaiser, U. (2017). In Situ Crystallization of the Insoluble Anhydrite AII Phase in Graphene Pockets. ACS nano, 11(8), 7967-7973.

-

Khestanova, E., Guinea, F., Fumagalli, L., Geim, A. K., & Grigorieva, I. V. (2016). Universal shape and pressure inside bubbles appearing in van der Waals heterostructures. Nature communications, 7.

-

Vasu, K. S., Prestat, E., Abraham, J., Dix, J., Kashtiban, R. J., Beheshtian, J., ... & Geim, A. K. (2016). Van der Waals pressure and its effect on trapped interlayer molecules. Nature communications, 7.

-

Koenig, S. P., Boddeti, N. G., Dunn, M. L., & Bunch, J. S. (2011). Ultrastrong adhesion of graphene membranes. Nature nanotechnology, 6(9), 543-546.

-

Yuk, J. M., Park, J., Ercius, P., Kim, K., Hellebusch, D. J., Crommie, M. F., ... & Alivisatos, A. P. (2012). High-resolution EM of colloidal nanocrystal growth using graphene liquid cells. Science, 336(6077), 61-64.

-

De Clercq, A., Dachraoui, W., Margeat, O., Pelzer, K., Henry, C. R., & Giorgio, S. (2014). Growth of Pt–Pd nanoparticles studied in situ by HRTEM in a liquid cell. The journal of physical chemistry letters, 5(12), 2126-2130.

-

Shin, D., Park, J. B., Kim, Y. J., Kim, S. J., Kang, J. H., Lee, B., ... & Novoselov, K. S. (2015). Growth dynamics and gas transport mechanism of nanobubbles in graphene liquid cells. Nature communications, 6, 6068.

-

Suenaga, K., Sato, Y., Liu, Z., Kataura, H., Okazaki, T., Kimoto, K., ... & Kaneyama, T. (2009). Visualizing and identifying single atoms using electron energy-loss spectroscopy with low accelerating voltage. Nature chemistry, 1(5), 415-418.

-

Linck, M., Hartel, P., Uhlemann, S., Kahl, F., Müller, H., Zach, J., ... & Lee, Z. (2016). Chromatic aberration correction for atomic resolution tem imaging from 20 to 80 kv. Physical review letters, 117(7), 076101.

-

Egerton, R. F. (2013). Control of radiation damage in the TEM. Ultramicroscopy, 127, 100-108.

-

Algara-Siller, G., Kurasch, S., Sedighi, M., Lehtinen, O., & Kaiser, U. (2013). The pristine atomic structure of MoS2 monolayer protected from electron radiation damage by graphene. Applied Physics Letters, 103(20), 203107.

-

Zan, R., Ramasse, Q. M., Jalil, R., Georgiou, T., Bangert, U., & Novoselov, K. S. (2013). Control of radiation damage in MoS2 by graphene encapsulation. ACS nano, 7(11), 10167-10174.

-

Atkins, P. (2010). Shriver and Atkins' inorganic chemistry. Oxford University Press, USA.

-

Mirwald, P. W. (2008). Experimental study of the dehydration reactions gypsum-bassanite and bassanite-anhydrite at high pressure: Indication of anomalous behavior of H 2 O at high pressure in the temperature range of 50–300 C. The Journal of chemical physics, 128(7), 074502.

-

Freyer, D., & Voigt, W. (2003). Crystallization and phase stability of CaSO 4 and CaSO 4–based salts. Monatshefte für Chemie/Chemical Monthly, 134(5), 693-719.

-

Algara-Siller, G., Lehtinen, O., Wang, F. C., Nair, R. R., Kaiser, U., Wu, H. A., ... & Grigorieva, I. V. (2015). Square ice in graphene nanocapillaries. Nature, 519(7544), 443-445.

-

Meyer, J. C., Eder, F., Kurasch, S., Skakalova, V., Kotakoski, J., Park, H. J., ... & Krasheninnikov, A. V. (2012). Accurate measurement of electron beam induced displacement cross sections for single-layer graphene. Physical review letters, 108(19), 196102.

-

Neto, A. C., Guinea, F., Peres, N. M., Novoselov, K. S., & Geim, A. K. (2009). The electronic properties of graphene. Reviews of modern physics, 81(1), 109.

-

Lee, C., Wei, X., Kysar, J. W., & Hone, J. (2008). Measurement of the elastic properties and intrinsic strength of monolayer graphene. science, 321(5887), 385-388.

-

Lehnert, T., Lehtinen, O., Algara–Siller, G., & Kaiser, U. (2017). Electron radiation damage mechanisms in 2D MoSe2. Applied Physics Letters, 110(3), 033106.

-

Balandin, A. A., Ghosh, S., Bao, W., Calizo, I., Teweldebrhan, D., Miao, F., & Lau, C. N. (2008). Superior thermal conductivity of single-layer graphene. Nano letters, 8(3), 902-907.

-

Li, H., Han, P. D., Zhang, X. B., & Li, M. (2013). Size-dependent melting point of nanoparticles based on bond number calculation. Materials Chemistry and Physics, 137(3), 1007-1011.

-

Jiang, H., Moon, K. S., Dong, H., Hua, F., & Wong, C. P. (2006). Size-dependent melting properties of tin nanoparticles. Chemical Physics Letters, 429(4), 492-496.

-

Xie, D., Wang, M. P., & Qi, W. H. (2004). A simplified model to calculate the surface-to-volume atomic ratio dependent cohesive energy of nanocrystals. Journal of Physics: Condensed Matter, 16(36), L401.

-

Mirjalili, M., & Vahdati-Khaki, J. (2008). Prediction of nanoparticles’ size-dependent melting temperature using mean coordination number concept. Journal of Physics and Chemistry of Solids, 69(8), 2116-2123.